Introduction and Defining the Scope

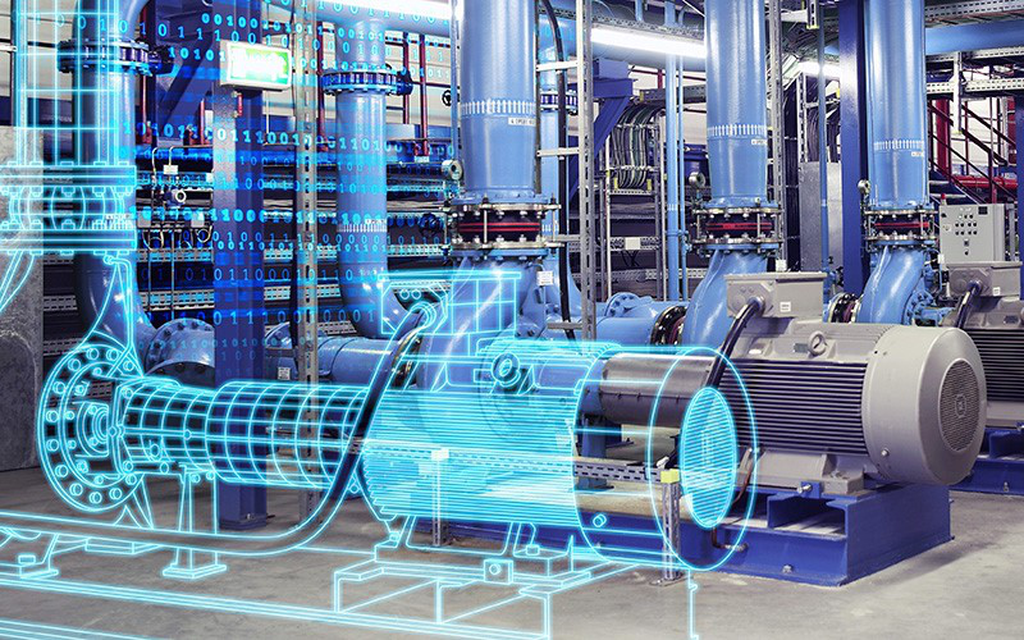

Introduction to Industries 4.0 as bridge between internet and physical world.

Use cases for industries 4.0

Uses of Industries 4.0 for Manufacturing 4.0, Agriculture 4.0, Health Care 4.0, Logistics 4.0 etc.

IoT: Connecting everything to the internet

Data Acquisition from physical Sources, public and private clouds and coping with data deluge

ESB: Controlling data flows

Strategies to make data transfer reliable, handle contention, guaranty sequencing and aging

Data Storage

Data Lakes, data cleansing and verification, pooling, public domain data sources, archiving

Data Analytics

Data Analytics makes use of fast algorithmic and the availability of big data to get new insights.

|

Human-Machine Collaboration

Industries 4.0 is the seamless cooperation between human workers and their machines.

Security, Safety, Reliability

Internet Infrastructure, Security, Safety and how to guarantee the availability of authentic data

Self-communicating Systems

Workflows, EDI, Woven production, Autonomous vehicles, Human machine interaction

Artificial Intelligence

Machine (Automated) Learning, Learning Machines, Machine games, Darwin Machines

Putting it all together

Putting a practical demo solution together to demonstrate the needs for Industries 4.0

Leadership for Industries 4.0

Concepts and methodology to orchestrate industries 4.0 related businesses and projects

|